Our EMS service for your business includes:

- Consulting in the field of DfT and DfM as well as layout support for board design

- Introduction of new manufacturing technologies for your project – we meet every challenge

- Development support: 3D printing, prototyping, PCBA samples and pre-series

- Data preparation and documentation

- Material procurement and obsolescence management

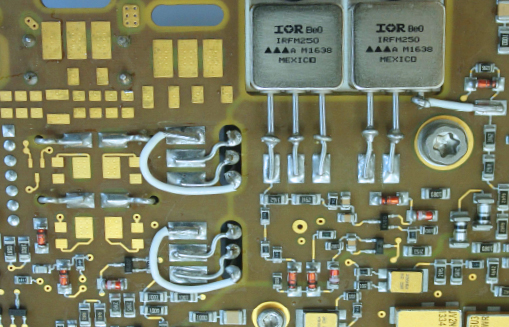

- PCB Assembly

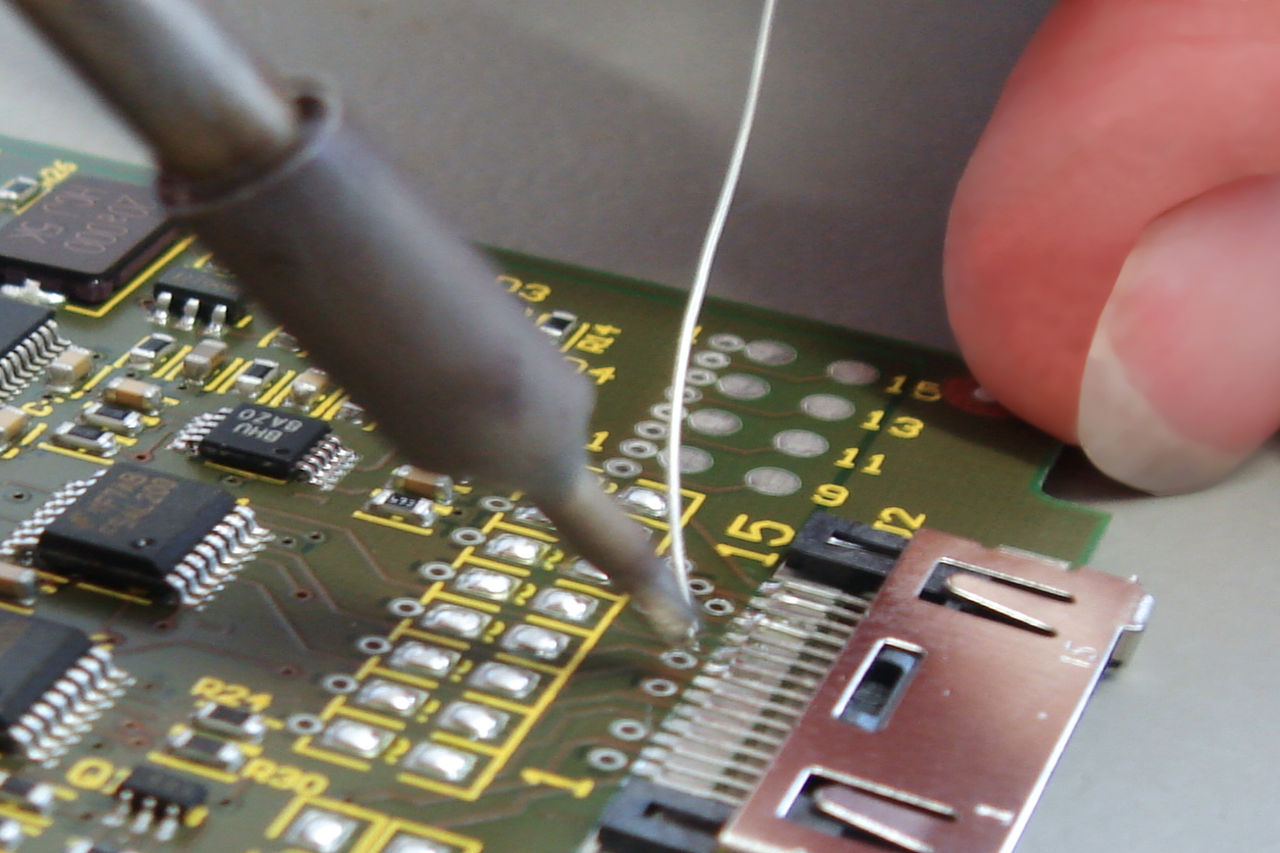

- Assembly services

- Industrialization preparation and PCBA or assembly production in series

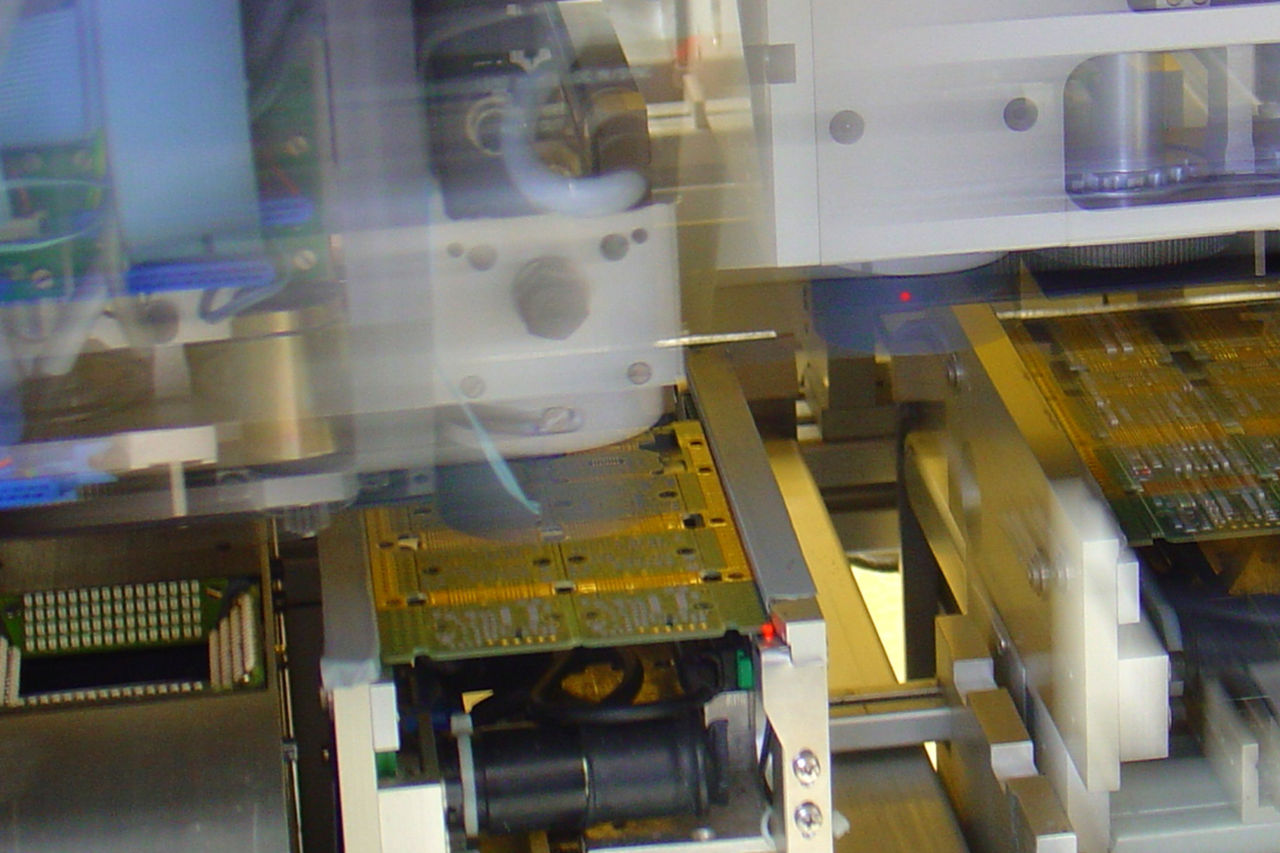

- Testing program creation with Merlin pro for TAKAYA flying probe systems

- Testing services from flying probe to final tests

- After-sales services: modifications & repairs

Want to learn more? Then just get in touch with us!