Typical topics of our project-related customer advice are:

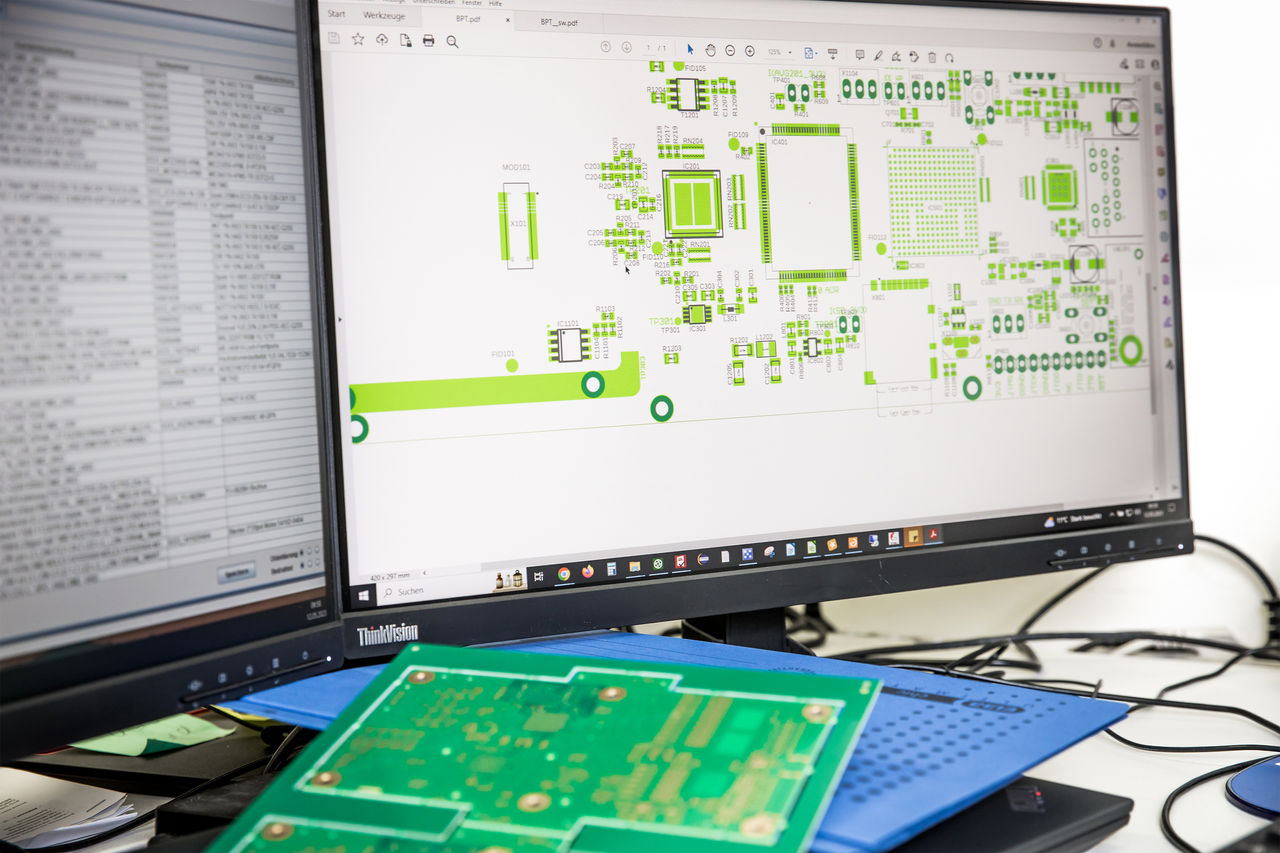

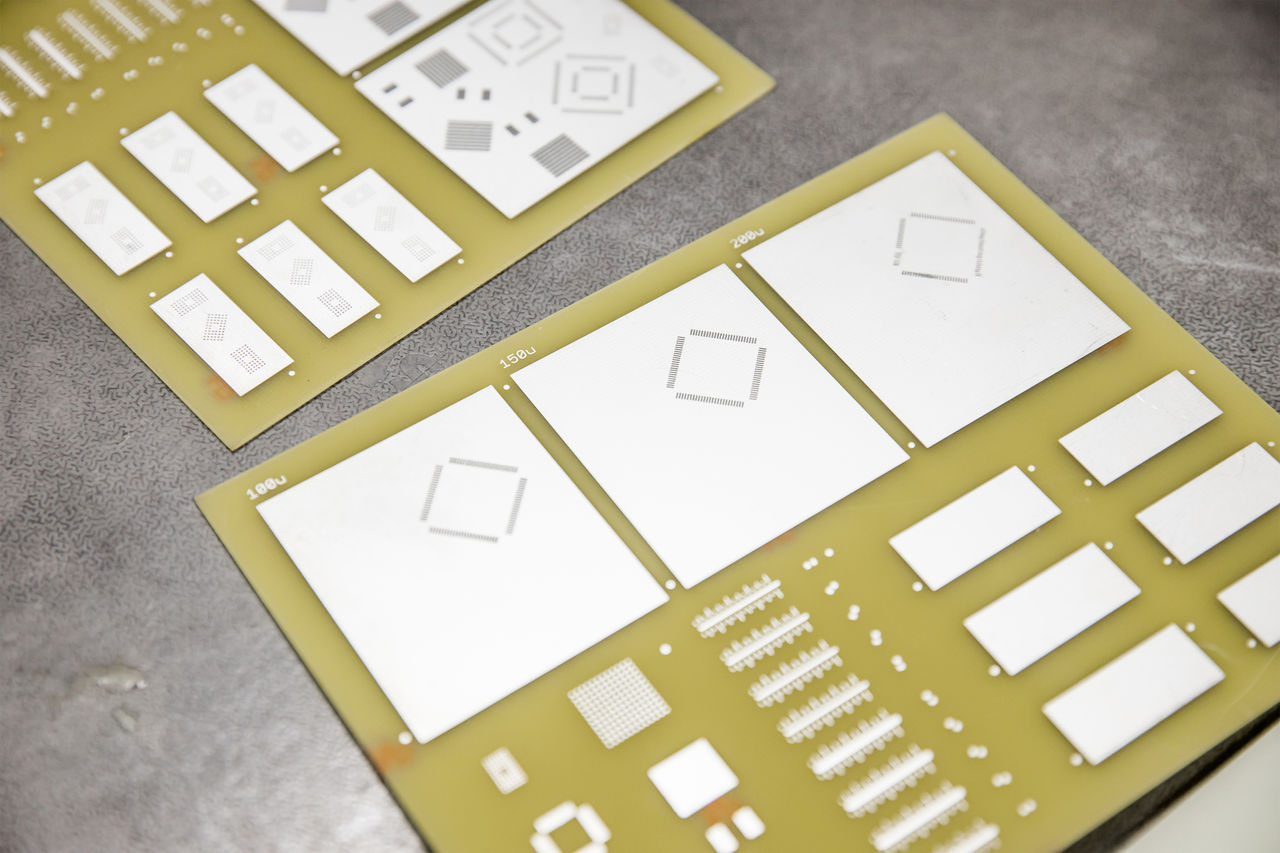

- Design verification during development: DfT (Design for Test to increase testability)

- DfMA (Design for Manufacturing and Assembly to Avoid Manufacturing Defects)

- Design for Procurement (DfP) - iComponent Analysis, Obsolescence Risk and Alternative Components

- Cost reduction already during prototype development and production

Want to learn more? Then just get in touch with us!