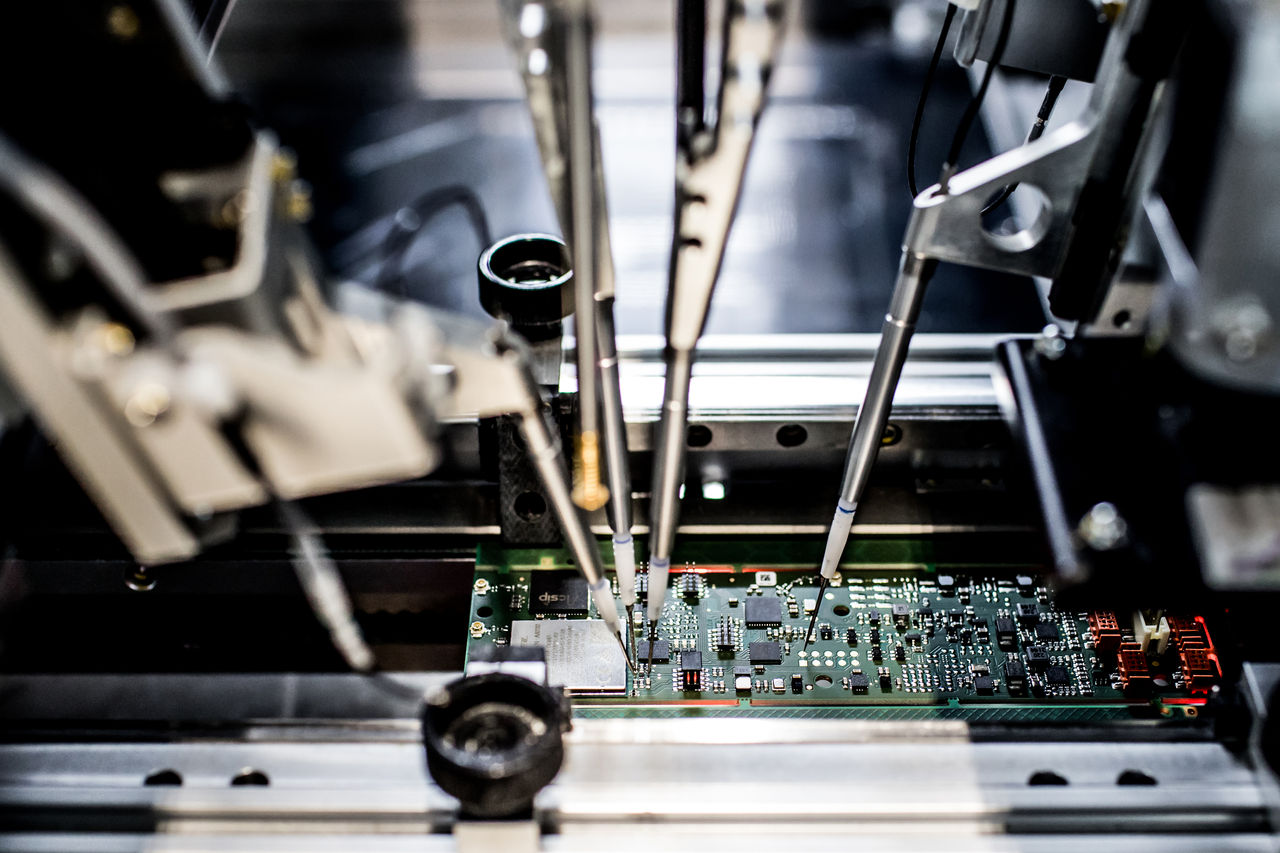

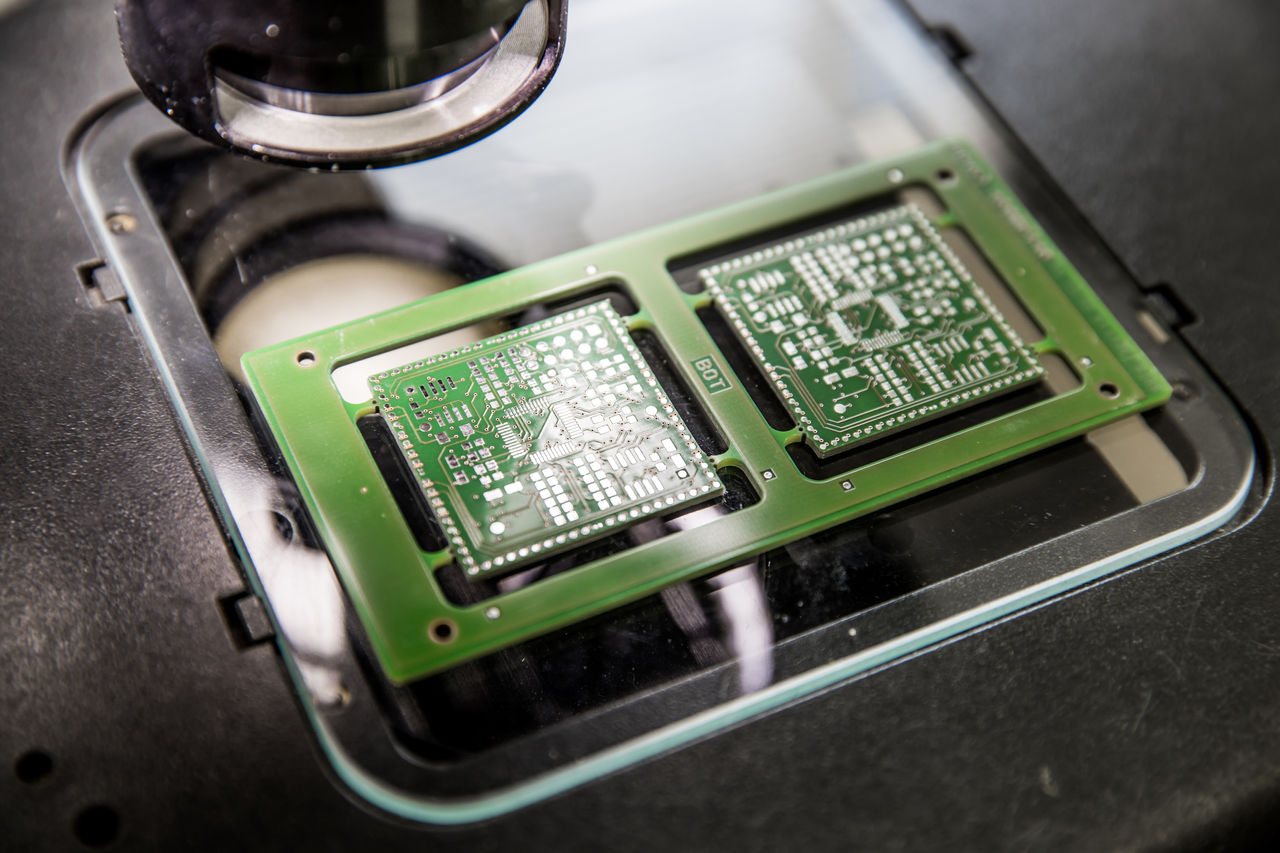

Our services in the flying probe test area:

- Short setup and test times due to efficient test program creation

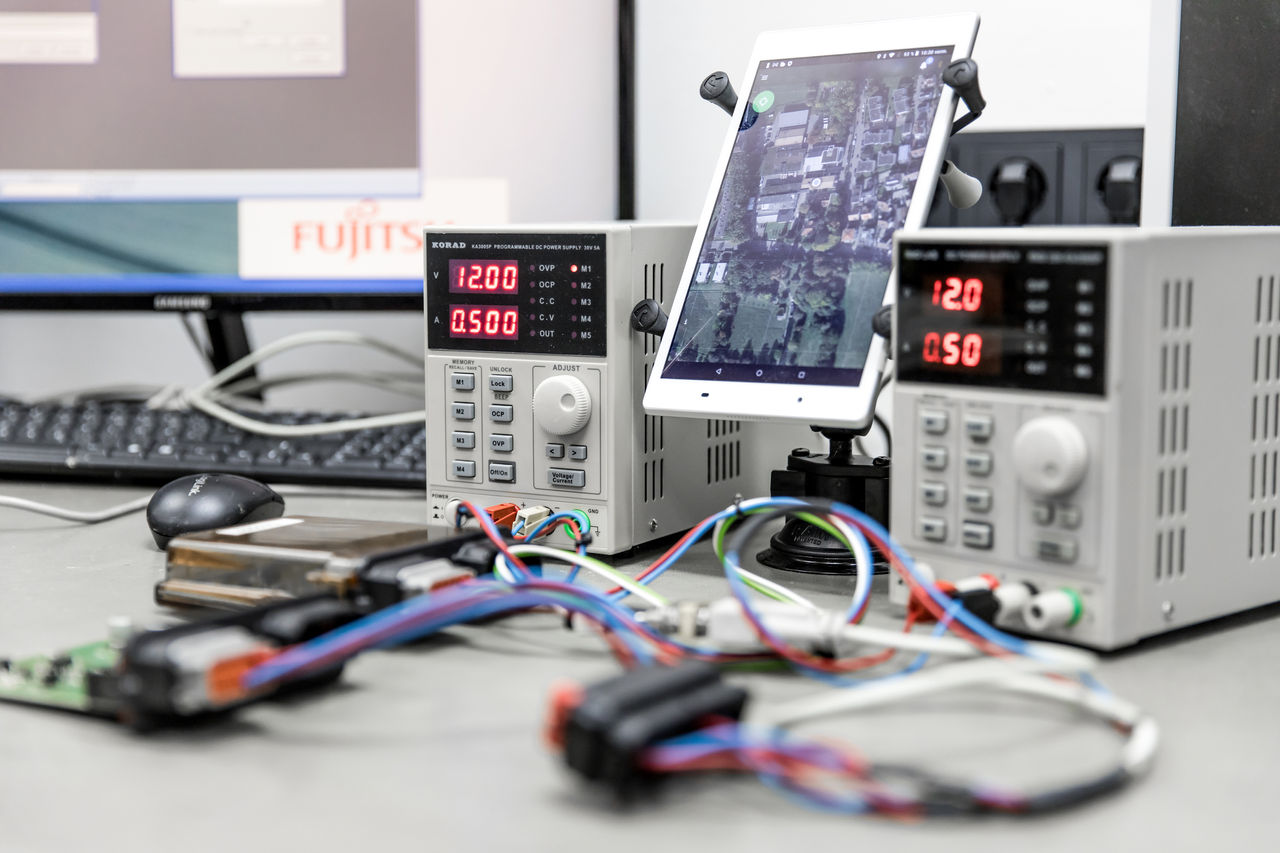

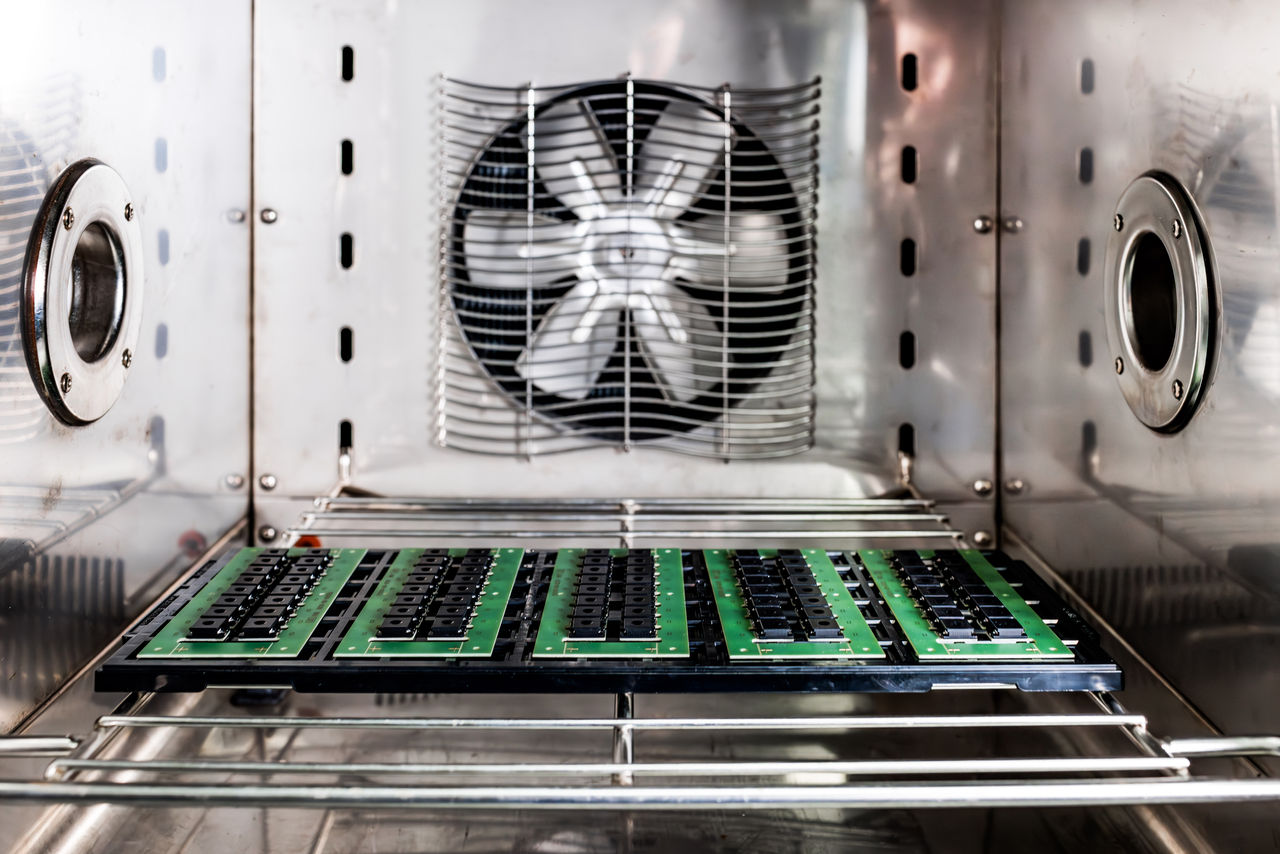

- Manufacturing Defect Analysis (MDA), Functional Tests (FCT) and Boundary Scan Tests (BST)

- On-board programming

- Optical tests (LED inspections, OCR text recognition)

- Wiring Harness Reviews

Your benefits:

- Cost savings through short setup and test times and efficient test program creation

- Cost savings due to the elimination of complex test adapters

- for small production batches: high variety of variants and complex structures on the printed circuit board, enormous time savings thanks to quickly executable tests with high test depth

- The automated creation of test programs from the CAD data enables an economical test from the first assembly, for which we use our software solution for effective data preparation and simple test generation

- the selection of the test scope can be made according to your assemblies (MDA test; current/voltage test, function test, boundary scan, on-board programming)

- Automatic documentation of test results

Do you have any questions? We will be happy to advise you. Then contact us directly !